Manufacturing is moving forward faster than ever, and technology is at the heart of this transformation. Among the most impactful tools today are laser cutting machines. In 2025, these machines are not just tools for precision—they are redefining efficiency, sustainability, and creativity in industries around the world. From small workshops to large-scale production plants, the demand for reliable and innovative laser cutting technology is growing steadily. By embracing new trends, manufacturers can stay competitive, reduce costs, and deliver products that meet today’s high expectations for quality and performance.

Laser Cutting Machine Trends Shaping Modern Manufacturing

Rise of smart automation

Intelligent automation is one of the most exciting developments in laser cutting technology. With the integration of artificial intelligence (AI) and Internet of Things (IoT), machines can now self-monitor, predict maintenance needs, and adjust for better accuracy, efficiency, and consistency during production.

This shift reduces downtime, increases productivity, and allows businesses to meet customer demands faster. In 2025, automation is no longer optional—it’s becoming the standard for manufacturers who want to compete globally while maintaining efficiency, scalability, and adaptability in the face of evolving industry challenges.

Energy-efficient models

Sustainability is influencing every industry, and laser cutting is no different. Modern machines are designed to deliver maximum performance while using less energy and reducing unnecessary overhead. By lowering power consumption, companies save money while also supporting greener operations and meeting growing environmental expectations.

These energy-efficient designs help reduce the environmental footprint of manufacturing without sacrificing precision or speed. As industries adopt eco-friendly practices, energy-conscious machines are proving a smart and future-ready plan for businesses of all sizes.

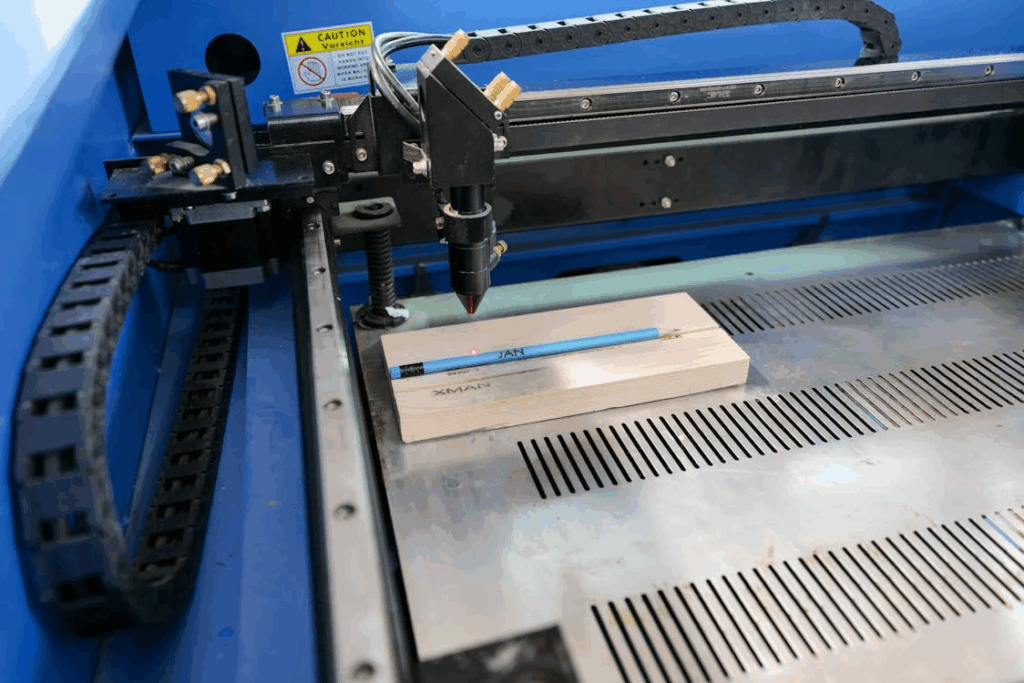

Compact and portable designs

Not every business operates a massive production floor. In response, manufacturers are developing compact and portable laser cutting machines. These smaller systems make it easier for small workshops, startups, and creative studios to access advanced technology and meet project needs efficiently.

Despite their size, compact machines still deliver impressive cutting power and versatility, offering the same performance benefits as larger systems. This trend is making high-tech manufacturing tools more accessible and affordable, helping businesses expand capabilities without significant spending in infrastructure.

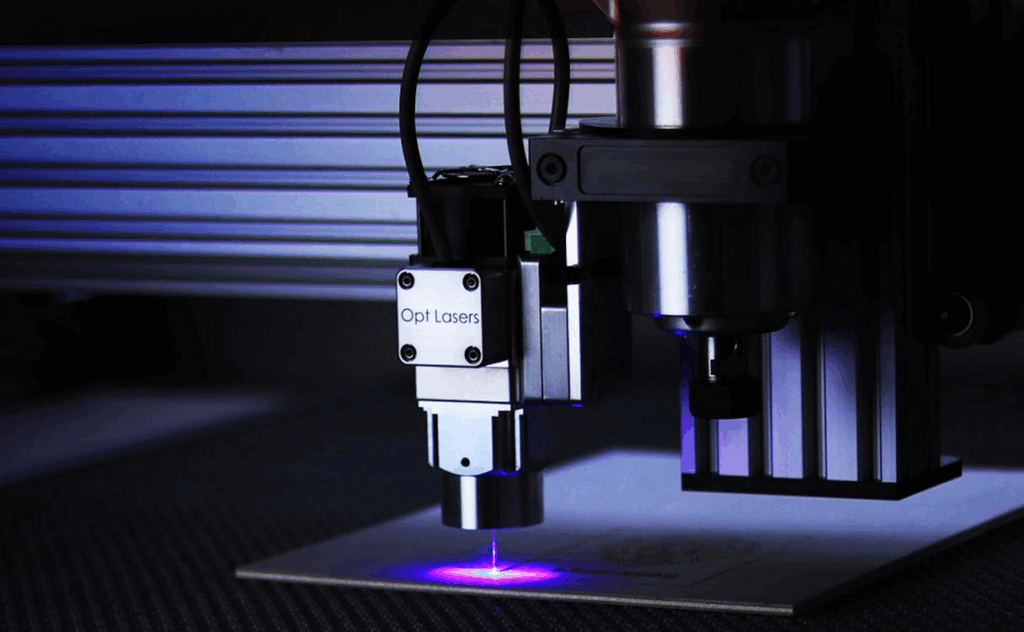

Advanced materials capability

Manufacturing is no longer limited to simple metals or plastics. Today’s laser cutting machines can work with a broader range of materials, including composites, advanced alloys, reflective metals, and modern industrial surfaces used in specialized sectors.

This flexibility opens new possibilities for industries like aerospace, automotive, and consumer products. The ability to cut complex materials with precision ensures that businesses can innovate without being limited by older technology, encouraging creativity, exploration, and continuous improvement in product design, manufacturing efficiency, and large-scale production strategies.

High-speed production

In 2025, speed is just as important as accuracy. Laser cutting machines are now faster than ever, reducing production times while maintaining high-quality results that customers expect across different industries.

High-speed cutting allows manufacturers to keep up with growing demand, handle larger orders, and reduce turnaround times significantly. This efficiency is vital for businesses looking to stay competitive in fast-moving industries where delivery timelines, reliability, and consistency often decide long-term success, customer loyalty, and overall brand reputation in the marketplace.

User-friendly interfaces

Operating a laser cutting machine used to require advanced technical knowledge. That is changing rapidly with the introduction of user-friendly interfaces. Modern machines now feature touchscreens, intuitive software, and simplified controls that guide operators every step of the way with clarity and consistency.

This makes it easier for employees to learn, reduces training time, and minimizes costly errors. By making technology more accessible, manufacturers empower more staff to confidently use advanced equipment, helping teams work faster while boosting overall productivity, efficiency, and workplace collaboration across diverse industrial operations.

Customization at scale

Customers in 2025 expect products that match their individual preferences. Laser cutting machines make this possible by combining precision with flexibility, allowing for unique designs in everyday production that stand out in competitive markets.

Manufacturers can now produce highly customized designs without slowing down production schedules or compromising quality. Whether it’s unique patterns, logos, or specialized components, customization at scale is transforming industries like fashion, automotive, and home décor, creating long-term value for both businesses and their clients while fueling creativity and innovation.

Sustainability focus

Sustainability is more than just a buzzword—it’s becoming a core principle in manufacturing. Laser cutting machines are helping businesses minimize waste by cutting materials with extreme precision and optimizing raw material usage across multiple applications and industries. This accuracy reduces leftover scraps and helps companies maximize efficiency with each project.

Combined with energy-efficient models, laser cutting supports a cleaner, greener approach to production. As global awareness grows, eco-conscious practices are becoming essential for brands that want to stand out, earn trust, and remain competitive in increasingly environmentally conscious markets.

Integration with robotics

One of the most groundbreaking trends is the integration of laser cutting machines with robotics. Automated arms and collaborative robots (cobots) are being paired with laser systems to streamline production workflows, improve safety, and reduce manual effort while optimizing speed.

This partnership increases accuracy, boosts workplace safety, and allows for 24/7 manufacturing with minimal supervision. Robotics integration is giving businesses the ability to scale up operations while maintaining consistent quality, helping them stay efficient, adaptive, and competitive in today’s fast-paced industrial environment.

Cloud connectivity

In 2025, cloud connectivity is emerging as a major trend in laser cutting technology. By linking machines to cloud-based platforms, businesses gain access to real-time data, performance tracking, and predictive insights that enhance overall efficiency.

This connectivity allows operators to monitor machines remotely, adjust production parameters, and quickly identify areas for improvement. It also enables seamless collaboration across locations, giving manufacturers the ability to share designs, track jobs, and maintain consistency at scale. Cloud-connected laser cutting ensures smarter decision-making, streamlined operations, and a competitive edge in a digital-first manufacturing environment.

Final Thoughts

In 2025, laser cutting machines are more than just tools—they are central to the future of modern manufacturing. From intelligent automation and energy efficiency to customization and sustainability, these machines are shaping how industries produce, innovate, and grow for years to come. With compact designs, advanced material capabilities, and robotic integration, laser cutting is becoming more versatile and accessible than ever before. For businesses aiming to stay ahead in a fast-changing world, adopting the latest laser cutting machine trends is no longer optional—it’s a decisive step toward lasting success.