You know that feeling when traditional manufacturing just can’t keep pace with your vision? Whether you’re running a startup or steering an established company, you’ve probably hit that wall where conventional methods feel painfully slow and expensive.

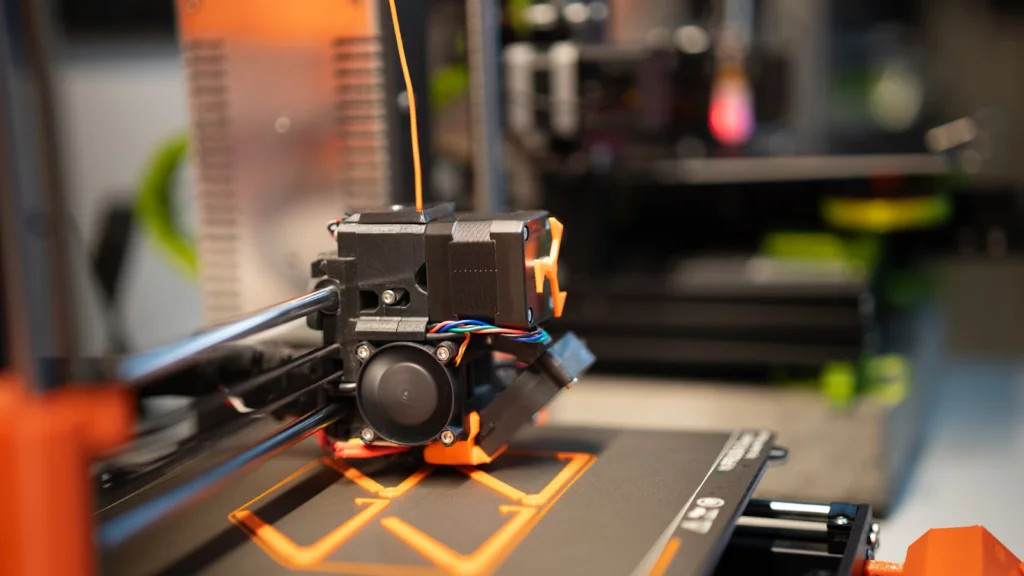

The way we design, build, and customize things has changed forever: thanks to online 3D printing services. From engineers prototyping new products to creating one-of-a-kind gadgets, 3D printing has moved from a niche tool to a mainstream solution.

What’s driving this shift? Speed, affordability, and the freedom to turn any idea into reality without the heavy upfront costs of traditional manufacturing. Let’s dive into the top ways people are using online 3D printing services today.

Rapid Prototyping for Product Development

Time is your most precious commodity in today’s hyper-competitive landscape. While your competitors are still stuck in lengthy development cycles, smart innovators are already three iterations ahead. The secret? Lightning-fast prototyping that turns your wild ideas into a tangible reality.

Accelerated Design Iterations for Startups

Picture this: you’re burning the midnight oil on your next breakthrough product. With traditional prototyping, you’d be twiddling your thumbs for weeks. But online 3d printing services flip that script entirely. Upload your design over morning coffee, and boom, physical prototypes land on your doorstep in mere days. No more theoretical guesswork. You’re holding real parts, testing real functionality, and making real progress while others are still waiting for their prototype.

Cost-Effective Testing Before Mass Production

Smart money says catch your mistakes early, not after you’ve committed to expensive production runs. Professional prototyping gives you materials that actually behave like your final products: no more crossing your fingers and hoping that a flimsy cardboard mockup represents reality. You’ll uncover those “aha!” moments and dodge those expensive bullets that would’ve cost you dearly down the line.

Multi-Material Prototype Development

Complex products demand sophisticated solutions. Modern prototyping services can actually print different materials together in one seamless build. Imagine eliminating assembly headaches while getting a prototype that truly represents your final vision. That’s the kind of efficiency that keeps you ahead of the pack.

Custom Manufacturing Solutions for Businesses

Today’s customers don’t want cookie-cutter products; they crave personalization. Meanwhile, you need manufacturing flexibility without drowning in inventory costs or minimum order nightmares. 3D printing for businesses delivers exactly that sweet spot you’ve been searching for.

On-Demand Production Without Inventory Costs

Remember those sleepless nights worrying about warehouse costs and unsold inventory? Kiss them goodbye. On-demand production means you create precisely what customers want, exactly when they want it. No more gambling on demand forecasts or tying up precious capital in products gathering dust. You produce, you sell, you profit—it’s beautifully simple.

Small-Batch Manufacturing for Niche Markets

Those specialized markets that big manufacturers ignore? They’re your goldmine. Traditional manufacturing economics say “forget about it” when volumes are low. But custom 3D printing laughs at those limitations. Suddenly, serving passionate niche communities becomes not just possible, but profitable.

Personalized Products at Scale

Mass customization sounds like an oxymoron, right? Not anymore. Each product can be uniquely tailored without setup costs or tooling nightmares. Whether you’re crafting personalized medical devices or custom automotive components, you’re delivering genuine value while maintaining streamlined operations.

Medical and Healthcare Applications

Healthcare isn’t just another industry—it’s where 3D printing genuinely saves lives and transforms patient experiences. Here, customization isn’t a luxury; it’s often the difference between suffering and healing.

Custom Prosthetics and Orthotics

Traditional prosthetics involve endless fittings and frustrating adjustments. 3D-printed alternatives change everything. Using precise body scans, you create perfectly fitted devices that actually feel comfortable. For kids who outgrow prosthetics faster than shoes, this technology is absolutely life-changing—replacing devices in days instead of months.

Surgical Planning Models and Guides

Surgeons are perfectionists by necessity. 3D printing applications give them something invaluable: practice runs. Before making that first incision, surgical teams can study physical models, rehearse complex procedures, and troubleshoot potential complications. The result? Better outcomes, shorter surgery times, and patients who heal faster.

Biocompatible Medical Devices

Medical-grade materials and sterile production environments enable creation of devices that integrate seamlessly with human biology. From dental implants to hearing aid components, you’re working with materials that bodies actually accept and thrive with.

Automotive and Aerospace Component Production

Weight matters when you’re pushing boundaries in automotive and aerospace. Every gram counts toward fuel efficiency, and every component must meet exacting performance standards under extreme conditions.

Lightweight Replacement Parts

Here’s something crucial: Using a 3D printer can pose several health concerns. These include potential exposure to ultrafine particles (particles smaller than 100 nanometers) and chemicals, and other possible safety hazards. Professional services eliminate these risks while delivering components with optimized internal structures—maintaining strength while dramatically reducing weight.

Custom Tooling and End-Use Components

Manufacturing fixtures and assembly tools represent hidden productivity goldmines. 3D printing produces these custom solutions quickly and affordably. Need modifications? No problem. Continuous improvement becomes genuinely continuous when you can iterate on tools as easily as designs.

Benefits of 3D Printing Through Online Services

Why struggle with expensive equipment when professionals offer superior capabilities? Online services deliver industrial-grade results without the massive capital investment or technical headaches.

Access to Industrial-Grade Equipment

Professional operations run machines worth hundreds of thousands of dollars; equipment that would bankrupt most businesses to purchase. You’re accessing superior accuracy, massive build volumes, and advanced materials that desktop printers can’t touch.

Professional Quality Control and Finishing

Experienced technicians ensure consistent results through proper machine calibration and material handling. The benefits of 3D printing extend far beyond raw printing to include professional finishing that achieves production-ready quality standards.

Global Accessibility and Fast Shipping

Online platforms connect you with local production facilities worldwide, slashing shipping times while maintaining competitive pricing. Even during peak demand, you’ll find available capacity somewhere in the network.

Final Thoughts on 3D Printing’s Future

Online 3d printing services have evolved from quirky novelty to indispensable business tools. We’re watching manufacturing transform before our eyes from life-saving medical breakthroughs to cutting-edge automotive innovations.

The democratization of advanced manufacturing isn’t coming; it’s already here. Your competitors are adapting. Your customers are expecting more. The real question isn’t whether this technology will reshape your industry; it’s whether you’ll be leading that transformation or scrambling to catch up. The choice is yours, and the time is now.

Common Questions About Online 3D Printing Services

What are 5 industries that 3D design is used in today?

3D printing is impacting healthcare, aerospace, education, manufacturing, automotive, and robotics. Other industries such as fashion, construction, consumer products, electronics, architecture, and food are also leveraging the technology.

What is 3D printing currently being used for?

3D printing is used to manufacture molds for making jewelry and even the jewelry itself. 3D printing is becoming popular in the customisable gifts industry, with products such as personalized models of art and dolls in many shapes in metal or plastic, or as consumable art, such as 3D-printed chocolate.

How do online 3D printing services compare to owning equipment?

Online services provide access to industrial equipment, professional materials, quality control, and finishing options that would cost $50,000-$500,000+ to replicate in-house, making them more cost-effective for most users.